HIGH PRESSURE COOLANT SYSTEMS

Product Description

Product Introduction

Pump

· The pump design has low vibration and low noise.

· Pumps of high quality and excellent performance are 100% made in Taiwan.

· Industrial ceramic plungers and special packing design are easy to maintain and have a longer service life.

· No auxiliary water tank design, which is easy to install. (Tool machine water tank capacity must be larger than 3 times the selected model.)

· Plunger pump provides stable pressure and water volume, regardless of the ratio of water-based cutting fluid or cutting oil.

Electronic Control System

· Variable-frequency motor control system saves energy.

· Multi-knife pressure option control can change the water pressure of knives at will.

· Multi-channel option allows users to choose 1, 2, 3 or 4 outlet channels as needed.

· Large 7” control panel screen and simplified control system make it easy for users to operate. Users can control the outlet channel by M code.

· The system will automatically stop to protect the pump from dry run.

· The Intelligent Detection System sends out warnings when there is filter failure or no water supply, and will alert users when the filter needs to be replaced.

· No dripping nozzles: the special hose design prevents nozzles from dripping when the user replaces the finished workpiece with the unfinished one, so that the machining environment is kept clean.

· The pump’s outlet volume automatically changes with the knife’s orifice and no overflow to the oil drum, which effectively reduces the temperature rise of the cutting fluid and improves the machining accuracy.

· When changing knife by M code, the system will automatically release the pressure to prevent inaccurate positioning due to residual pressure.

Cooling System

· Air-cooled oil cooling system solves the problem of rising cutting fluid temperature and prevents inaccurate processing resulting from different temperatures of the cutting fluid.

· If precise oil temperature is required, this system can reduce the needed refrigeration to save energy.

· Air-cooled fan overcomes the difficulty of cooling the oil cutting fluid.

· For oil cutting fluid only.

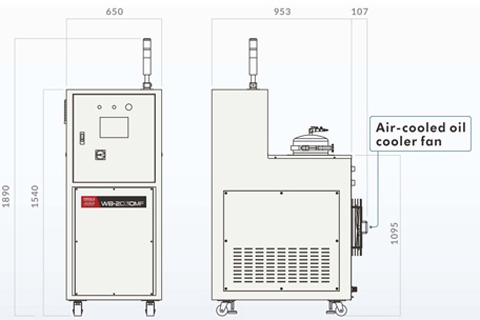

Specification

|

Model |

Working Pressure |

Suction Volume |

Horsepower |

|||

|

HP |

Φ |

Volt |

Hz |

|||

|

WB-2030MF |

70 |

34 |

7.5 |

3 |

220 |

60 |

※1). Filters of 5µ, 25µ, 50µ are available; standard equipped with 5µ.

2).Voltage and frequency can be customized.

*THE SPECIFICATION IS SUBJECT TO CHANGE WITHOUT NOTICE FOR THE PURPOSE OF IMPROVEMENT OF THE PRODUCT.